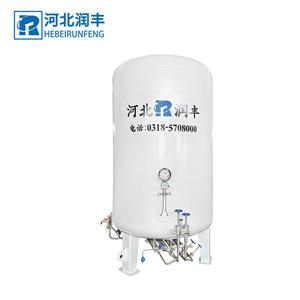

The natural gas storage tank is a double-layer structure tank for storing cryogenic liquid to bear the pressure of medium and the low-temperature tank is made of low-temperature resistant alloy steel (0Crl8Ni9) shell. A certain distance is maintained between the protective layer of the tank and the tank to form an insulation space to bear the gravity load of the tank and medium and the vacuum negative pressure of the insulation layer. The shell is made of vessel steel without contact with low temperature, and the insulation layer is mostly filled with pearlescent sand for high vacuum pumping. The evaporation rate of low-temperature storage tank is generally lower than 0.2%.

II Schematic diagram of decompression and pressurization of low temperature storage tank:

The outlet of natural gas storage tank is powered by the self pressure of the storage tank. After the liquid is sent out, the liquid level drops and the gas phase space increases, resulting in the pressure drop in the tank. Therefore, it is necessary to continuously add gas to the tank to keep the pressure in the tank unchanged in order to meet the process requirements. As shown in Figure 2, a pressurized vaporizer and a pressurized valve are set under the storage tank. The pressurized gasifier is an air heated gasifier, and its installation height shall be lower than the minimum liquid level of the natural gas storage tank. The action of the booster valve is opposite to that of the pressure reducing valve. When the outlet pressure of the valve is lower than the set value, it opens and the pressure rises above the set value, it closes. The pressurization process is as follows: when the pressure in the tank is lower than the set value of the pressurization valve, the pressurization valve is opened, and the liquid in the tank slowly flows into the pressurization vaporizer by the liquid level difference. The gas generated by liquid gasification flows through the pressurization valve and the gas phase pipe and is supplemented to the tank. The continuous supplement of gas makes the pressure in the tank rise. When the pressure rises above the set value of the booster valve, the booster valve closes. At this time, the pressure in the pressurized vaporizer will prevent the liquid from flowing into the pressurization process.