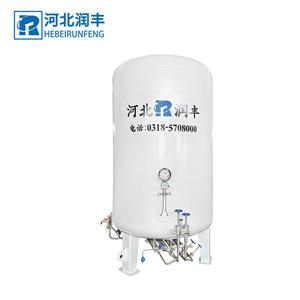

Exploring the Cryogenic Cylinder (Dewar)

Have you ever wondered how those shimmering tanks store and transport essential gases at mind-numbingly cold temperatures? The cryogenic cylinders, also known as a Dewar flasks are the marvels of engineering, hold the key to a plethora of applications, from medical research to aerospace engineering. Buckle up as we delve into their structure, uses, and advantages over their traditional counterparts.

1. Unveiling the Layers: Anatomy of a cryogenic cylinder (dewar)

Imagine a thermo isolation dewar cylinder, with multiple layers working together to maintain low temperatures. A typical Dewar cylinder consists:

Inner Vessel: Crafted from stainless steel, can safely hold the cryogenic liquids, like liquid nitrogen, oxygen, argon, carbon dioxide or liquid natural gas.

Multi-Layer Insulation: Think of this as the magic barrier. Layers of vacuum, superinsulation, and radiation shields create a near-impenetrable wall against heat transfer from the environment.

Outer Shell: Providing structural integrity and sheltering the inner layers, this shell is often made of durable materials like stainless steel or carbon steel.

Additional Features: Depending on the purpose, Dewar cylinders may come equipped with pressure relief valves, level sensors, pressure gauge, and transfer pipelines for safe and efficient operation.

2. A Universe of Chilling Applications:

Cryogenic cylinders aren't just fancy thermoses, they're workhorses across various industries:

Medical Miracles: Preserving biological samples, powering cryotherapy treatments, and even storing organs for transplantation.

Industrial Gases: Safely storing and transporting liquefied gases like oxygen, nitrogen, and argon for various industrial processes like metal cutting and food freezing.

Space Exploration: Fueling rockets and spacecraft, and keeping astronaut life support systems operational.

Scientific Research: Conducting experiments at extreme temperatures, studying material properties under cryogenic conditions, and facilitating microscopy of tiny structures.

3. Why Dewar, Why Not?Advantages over Traditional Gas Cylinders:

Beyond the cool factor, Dewar cylinders offer several distinct advantages over traditional gas cylinders:

Superior Efficiency: The multi-layer insulation significantly reduces evaporation, meaning less frequent refills and lower costs.

Larger Capacity: Pack more punch! Dewar cylinders hold significantly more liquid, reducing transportation needs and increasing efficiency.

Enhanced Safety: Advanced pressure relief systems and leak detection features minimize safety risks associated with high-pressure gases.

Greater Versatility: With a wider range of temperature tolerance and customizable features, Dewar cylinders cater to diverse applications.

4. The Future:

As technology advances, cryogenic cylinders are evolving too. Expect innovations like even better insulation materials, remote monitoring systems, and even self-pressurizing capabilities.

So, the next time you encounter a Dewar cylinder, remember the intricate engineering and diverse applications that lie beneath its frosty exterior. They're not just cool containers; they're enablers of scientific advancements, industrial processes, and even life-saving medical procedures. Now that you're in the know, go forth and spread the word about the wonders of cryogenic technology. If you have any further questions or would like to delve deeper into specific aspects, feel free to ask!