In recent years, the low-temperature liquid market has become increasingly prosperous. The sales of liquid oxygen, liquid argon, liquid nitrogen, liquid carbon dioxide and LNG natural gas have increased significantly. Therefore, the profit of oxygen generator by-products is very considerable, and it has become an important part of the non steel commodity income of iron and steel enterprises. The production, storage and transportation of cryogenic liquids cannot be separated from cryogenic storage tanks, which are widely installed and used.

The thermal insulation storage tank is divided into vacuum powder insulation type and atmospheric pressure powder insulation type. Powder insulation uses powder, fiber or foam materials with low thermal conductivity to reduce heat transfer. There are two ways: one is to use general powder insulation (stacking insulation) under atmospheric pressure. The insulation layer is thick, and dry nitrogen is filled to maintain positive pressure to prevent moisture from entering and condensing. It can be applied at least above the liquid nitrogen temperature; Another kind of vacuum powder insulation is to vacuum the space filled with powder, which reduces the heat transfer of gas. At the same time, the powder particles also weaken the radiation heat transfer, making the insulation effect very good.

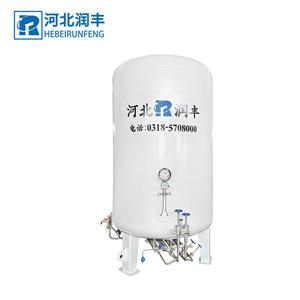

The vacuum powder low-temperature storage tank is a double-layer cylinder structure. The inner cylinder and its piping are made of austenitic stainless steel. The shell is made of carbon steel. The interlayer is filled with expanded perlite (also known as pearlescent sand) and is equipped with specially treated adsorbent. It is pumped into a high vacuum (0.5 ~ 6pa) with a capacity of less than 200m3. The working pressure is high (the working pressure of the two argon storage tanks for ladle bottom blowing in workshop 4 is 2.0 MPa), and there is a vaporizer outside the tank, which can not only boost the pressure in the tank for vehicle filling, but also directly send out the pressure gas. According to its use, it can be divided into fixed type and transport type. The fixed type is mainly used for the storage of cryogenic liquids. It is installed in the production place, application point or supply station of cryogenic liquids; The transportation mode transports cryogenic liquids from the place of production or supply station to the point of use. There are often land transportation, water transportation and other modes. They are called tank cars, trailers and tankers respectively.

The atmospheric powder cryogenic storage tank is of flat bottom double-layer structure, the inner tank is made of stainless steel, the shell is made of carbon steel, the inner tank contains medium, the interlayer between the inner tank and the shell forms a cold insulation space, the inner tank shell is of flat bottom structure, and the tank top is spherical. The inner tank and the bottom of the shell are insulated with foam glass bricks, and the interlayer is insulated with pearlescent sand. The shell is equipped with a rotating winding ladder, and the top of the groove is equipped with an operation channel and a safety fence. The capacity is more than 200m3, and the maximum capacity in China is 2000m3, which is far away from foreign countries. The working pressure is low, ranging from 34kpa to 40kpa. The filling depends on the liquid pump or liquid level difference. It can also be used as oxygen peak shaving gas supply. When the oxygen generator stops for a short time or the oxygen pressure is low, it is put into use. After being pressurized by the pump, it is vaporized by the vaporizer and sent to the pipe network