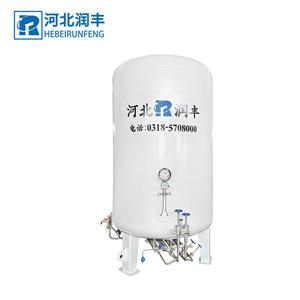

Dewars have two main advantages: The first is that they can hold large quantities of gas at relatively low pressures compared to compressed gas cylinders.

2. The second is that it provides an easily manipulated cryogenic liquid source.

3. Due to the firmness and reliability of the Dewar tank, long retention time, and its own gas supply system, its built-in vaporizer can continuously output normal temperature gases (oxygen, nitrogen, argon) with a flow rate of up to 9.2m3/h, and the maximum constant output pressure of the gas can reach 1.2MPa (medium pressure type) / 2.2 MPa (high pressure type), fully meeting the gas consumption requirements under normal circumstances.

4. If the gas flow rate of the user is large, multiple Dewar tanks can be connected in parallel or an external vaporizer can be installed to meet the gas supply requirements.

5. By installing an external vaporizer, the maximum output flow of a single Dewar tank can reach 30m3/h.

6. Dewar tanks can provide diversified uses: ◆Direct gas supply at the work site, which is similar to compressed gas cylinders; ◆Small and simple pipeline centralized gas supply; ◆Cryogenic liquid use, etc.

7. Advantages of Dewar tanks: ◆The storage pressure is low, multi-level safety protection devices are set, the safety is better, and the operation is simple and reliable.

8. ◆Large storage capacity, the gas storage capacity of a hexagonal gas cylinder is equivalent to nearly 30 cylinders of cylinder gas (oxygen, nitrogen, argon).

9. Therefore, the storage space can be reduced, the operation of changing bottles can be reduced, and the work efficiency can be improved.

10. For the centralized gas supply of pipelines, the investment in busbars can be reduced.

11. ◆The bottle body is clean, and the purity of the supplied gas is higher.

12. Because the liquid gas is directly vaporized and supplied, it avoids the potential quality hazards caused by secondary pollution due to many links in the process of cylinder gas filling, transportation and use.

13. Usually output oxygen purity ≥ 99.2%, nitrogen purity ≥ 99.999%, argon purity ≥ 99.995%, carbon dioxide purity ≥ 99.9%.

14. ◆High gas utilization rate: After every use of cylinder gas, there must be residual pressure, while the liquid gas supply of the hexagonal gas cylinder can avoid any waste and reduce the cost of gas consumption.

15. ◆The self-weight of the hexagonal gas cylinder is about 116Kg, and the total weight after being filled with liquid gas is about 300Kg, while the total weight of compressed gas in 30 cylinders with the same amount of gas is nearly 2000 Kg.

16. Therefore, the auxiliary cost of transportation and manual loading and unloading can be greatly reduced.

17. ◆With automatic pressure boost control, circuit saving, built-in carburetor, pressure and liquid level indicating device, high integration.

18. ◆Use advanced technology to improve the production environment and enhance the corporate image.

19. ◆It does not need any kinetic energy, is not affected by power outages and water outages, and can work around the clock.