Demystifying the Deep Freeze: A Guide to Cryogenic Tanks

Imagine a world where temperatures plummet to unimaginable depths, where gases condense into shimmering liquids, and where specialized vessels hold the key to scientific advancements and industrial processes. Welcome to the realm of cryogenics, and at its heart lies the mighty cryogenic tank.

What is a Cryogenic Tank?

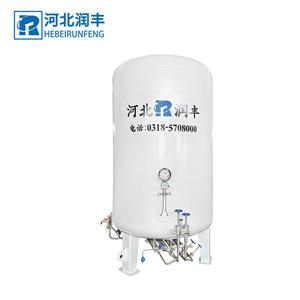

A cryogenic tank is a specially designed container used to store and transport materials at extremely low temperatures, typically ranging from -150°C to -270°C (-238°F to -454°F). These tanks, often resembling giant thermos flasks, play a crucial role in various industries, from healthcare and aerospace to food processing and energy.

The Art of Crafting the Cryogenic tanks:

Producing a cryogenic tank is a meticulous process that demands precision engineering and high-quality materials. Here's a simplified glimpse into the journey:

1. Inner Vessel: The inner vessel, usually crafted from stainless steel, holds the cryogenic liquids. Its design prioritizes strength, thermal insulation, and leak prevention.

2. Multi-layer Insulation: This critical layer forms the heart of the tank's temperature-shielding abilities. Multiple layers of materials like vacuum, superinsulation, and radiation shields work together to minimize heat transfer from the environment.

3. Outer Shell: The outer layer, often made of carbon steel or stainless steel, provides structural support and protects the inner components from external damage.

4. Additional Features: Depending on the tank's purpose, it is normally equipped with pressure relief valves, level sensors, pressure gauges, level gauges and transferpipelines for safe and efficient operation.

Where the Cryogenic Comes in Handy.

Cryogenic tanks have a diverse range of applications, playing a vital role in:

Medical research: Storing biological samples, preserving organs for transplantation, and powering cryotherapy treatments.

Industrial gas storage: Safely storing and transporting liquefied gases like liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide and liquid natural gas for various industrial processes.

Food processing: Freezing and preserving food products, maintaining optimal cold chain conditions.

Space exploration: Propelling rockets and spacecraft, cryogenically storing fuel and life support systems.

Scientific research: Conducting experiments at super-cold temperatures, studying material properties under extreme conditions, and facilitating cryogenic microscopy.

Choosing the Right Cryogenic vessel:

With so many applications and variations, selecting the right cryogenic tank requires careful consideration. Here are some key factors to consider:

Capacity: Choose a tank size that aligns with your storage or transport needs.

Material: Consider the compatibility of the tank material with the specific cryogenic liquid you'll store. Of course the ambient temperature is an important factor to consider while choosing the right material for ourter vessel.

Pressure rating: Ensure the tank can withstand the internal pressure generated by the stored liquid.

Insulation performance: Opt for a tank with superior insulation to minimize liquids loss and maintain stable temperatures.

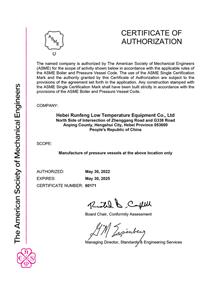

Supplier reputation: Choose a reputable manufacturer with a proven track record of quality and safety.

By carefully evaluating these factors and seeking expert advice, you can select the perfect cryogenic tank to meet your specific needs and keep your valuable materials chilled to the core.