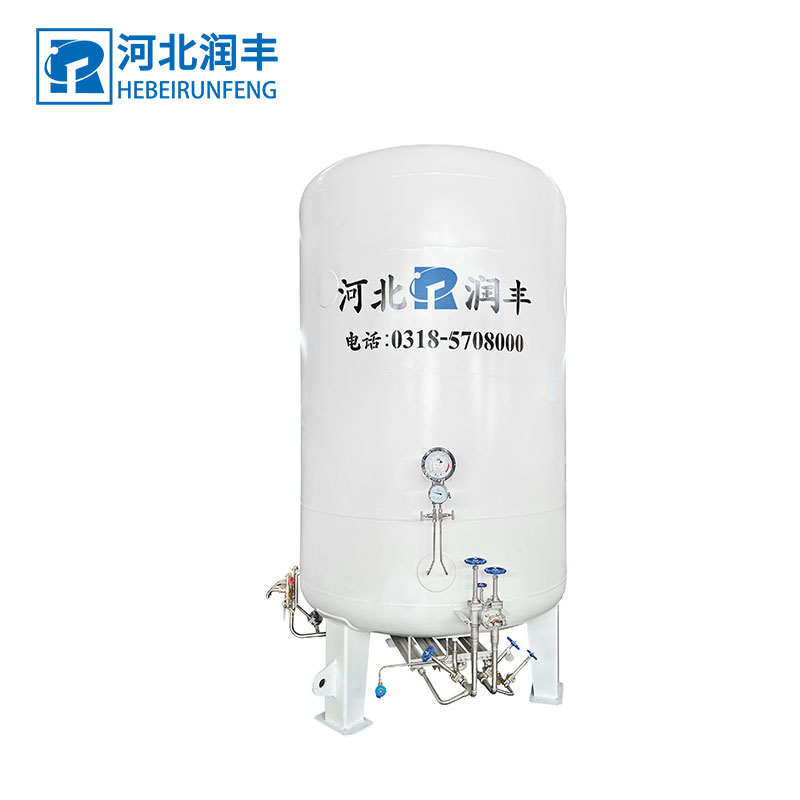

Liquid Nitrogen Tank

Brand :HEBEI RUNFENG

Product origin :China

Liquid Nitrogen Tank,Automated equipment testing and production ensures the production efficiency of the product. The production process of layer-by-layer inspection makes customers more assured. Through continuous technical accumulation, Runfeng series of cryogenic storage tank products and business scale have always been in the forefront of the country. Provide industry users with overall solutions in various fields from storage to industrial applications, fully meeting the needs of industry users.

Product Description

Liquid Nitrogen Tank. Automated equipment testing and production ensures the production efficiency of the product. The production process of layer-by-layer inspection makes customers more assured. Through continuous technical accumulation, Runfeng series of cryogenic storage tank products and business scale have always been in the forefront of the country. Provide industry users with overall solutions in various fields from storage to industrial applications, fully meeting the needs of industry users.

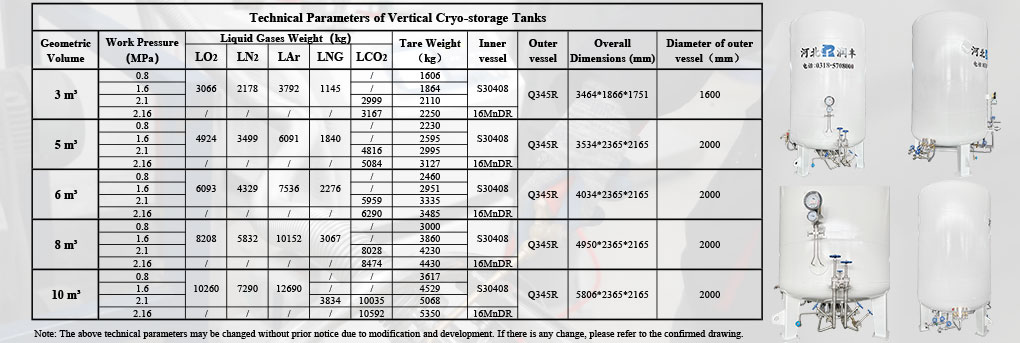

Model: 1m³---500m³

Pressure: 0.8Mpa---3.5Map

Application scenarios: food processing, medical industry, cutting industry, etc.

Capacity: 1m³--200m³ 100 units per month

Specification

Main Features

1.Many years experience in cryogenic liquid storage tank's designing and manufacturing.

2.Professional and powerful team to support the business of our company.

3.Superior raw material to make the high quality products.

4.Various kinds of cryogenicliquid storage tank can be proveded for and customized products can also be accepted.

Detailed Images

S30408 Inner Tank Weldin | Head top welding |

Internal piping design | Pipe assembly | Finish product Inspection |

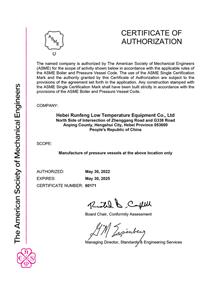

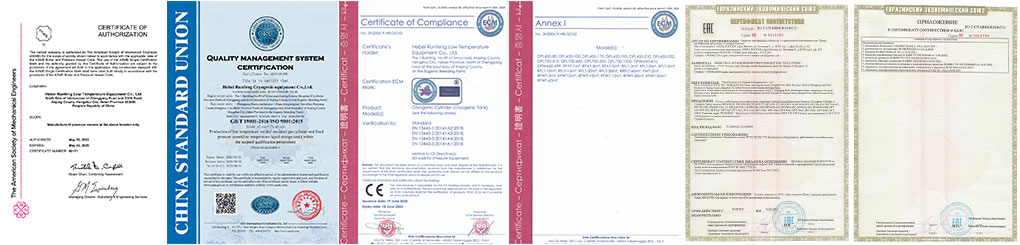

Certifications

-

Download

- tanks技术信息表.pdf