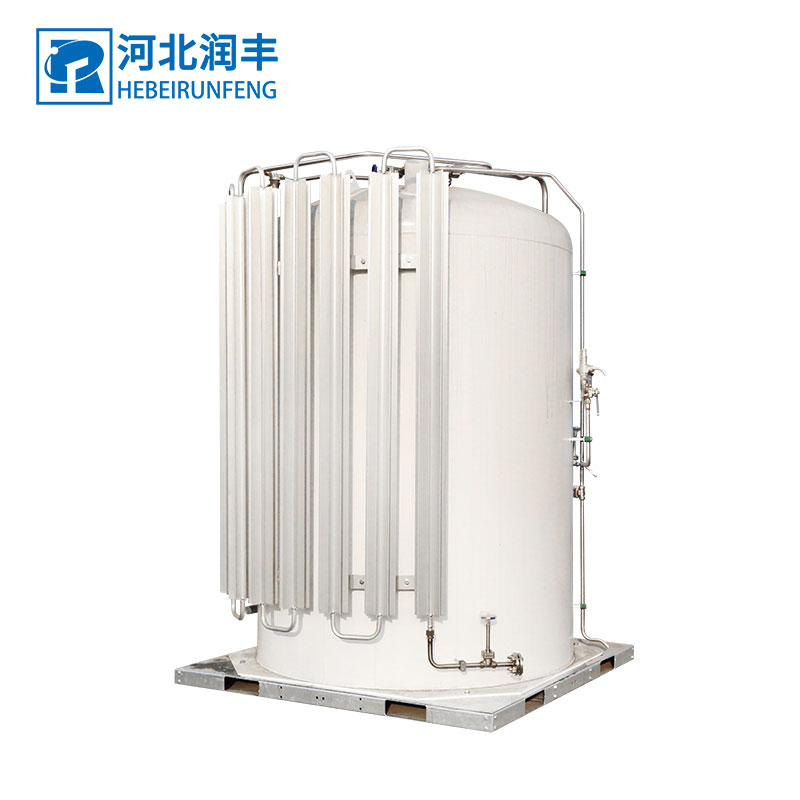

Microbulk Tank

Brand :HEBEI RUNFENG

Product origin :China

Microbulk Tank : Small cryogenic liquid storage tank, which is composed of tank skid, has the advantages of compact structure, low evaporation rate, small footprint, centralized control, safety and reliability, and convenient operation and maintenance. Products are suitable for various fields such as food industry, medical industry, industrial production, welding and processing. The use of high vacuum multi-layer insulation technology makes the product lighter and more convenient for customers to use.

Can be customized according to customer needs

Product Description

Microbulk Tank:Small cryogenic liquid storage tank, which is composed of tank skid, has the advantages of compact structure, low evaporation rate, small footprint, centralized control, safety and reliability, and convenient operation and maintenance. Products are suitable for various fields such as food industry, medical industry, industrial production, welding and processing. The use of high vacuum multi-layer insulation technology makes the product lighter and more convenient for customers to use.

Can be customized according to customer needs

Model: 1m³--10m³

Pressure: 0.8Mpa--3.5Mpa

Application scenarios: food processing, industrial welding, medical industry, etc.

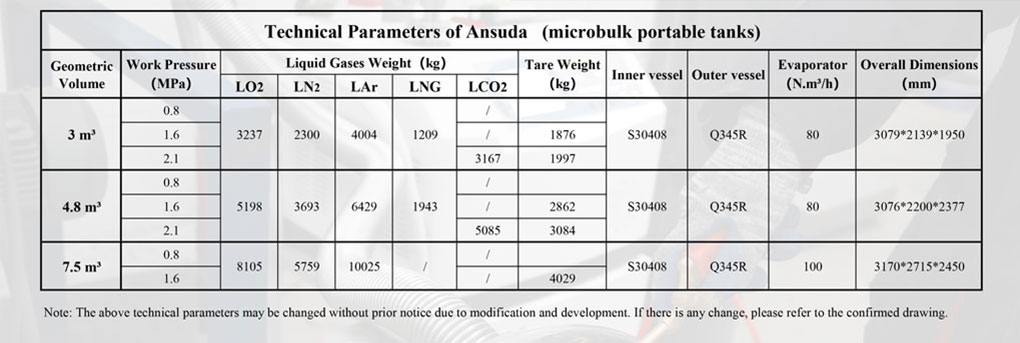

Specification

Main Features

4. Cryogenic liquid filling can be realized on site, which is a good solution to the shutdown caused by gas supply.

Application Fields

Microbulk tanks can be widely used in various industries, such as laser processing, electronics, scientific research, chemical engineering, welding, medical, food industry etc. The vessel has a compact structure with a small footprint.

Detailed Images

Metal Sheet Rolling | S30408 Inner Tank Weldin | Head top welding |

Internal piping design | Pipe assembly | Finish product Inspection |

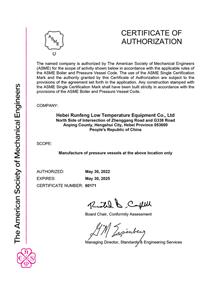

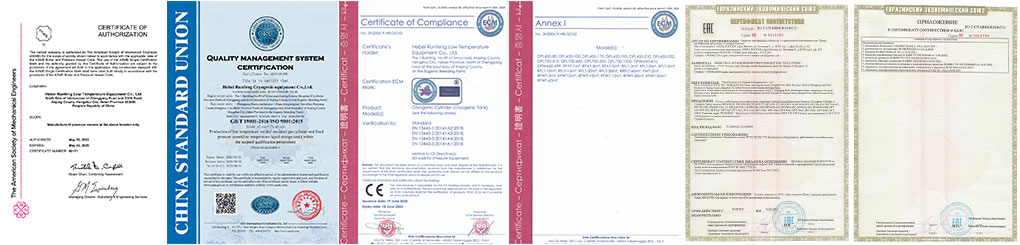

Certifications

-

Download

- tanks技术信息表.pdf