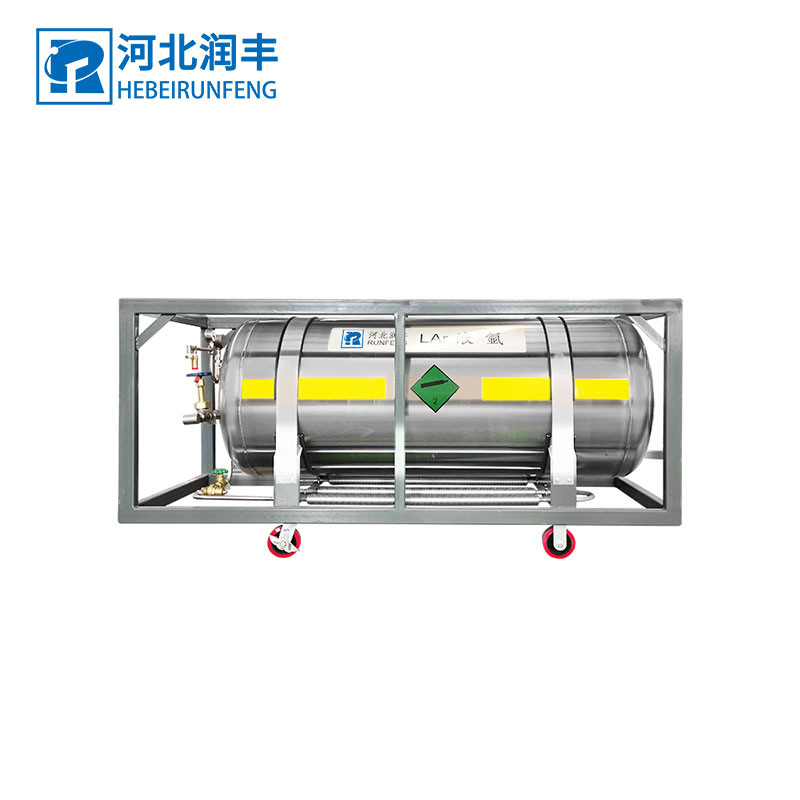

Liquid Argon Cylinder

Brand :HEBEI RUNFENG

Product origin :China

Delivery time :0~35days

Supply capacity :3000 pcs per month

Liquid Argon Bottle is mainly used for storage and transportation of liquid argon in the welding, smelting, semi-conductor industry such as chip production, aero engine manufacturing and other high-precision industrial fields. Compared with traditional steel cylinders, liquid argon dewars are easier to use and transport. The dewars we provide are vacuum with double vessels and have low evaporation rate. The design of safety valve and bursting disc ensures the bottle body 100% safe and non-hazardous. Multi-level safety inspection ensures products possess high quality standard before leaving the factory.

Product Description

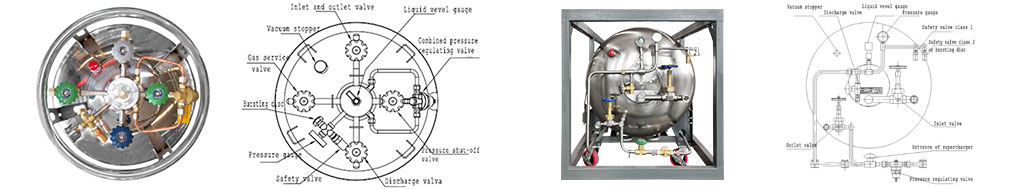

Liquid argon dewar bottle is mainly composed of inner and outer shell, thermal insulation structure, pipeline system and operation & safety accessories.

Process system: 1. Liquid inlet system; 2. Liquid level and pressure measuring system; 3. Complete indication system; 4. Safety system; 5. Drainage system; 6. Ventilation system; 7. Vacuum system; 8. Booster system.

Dewar bottles can be installed and produced according to the accessories made by customers. At the same time, we can provide booster pump, vaporizers and other supporting facilities. The product has a mirror finish. The exquisite shape design details show the unique ingenuity of the product and fully display the image, quality and value of Hebei Runfeng.

Specification

| Overall Dimensions and Technical Parameters for Liquid Cylinders | ||||||||||||

| Type | Gross Capacity (L) | Working Pressure (MPa) | Tare Weight(Kg) | Max. Theoretical Max. Filling Volume(Kg) | Overall Dimension(mm) | Safety Valve Setting Pressure | Secondary Safety Valve for LNG (Mpa) | Bursting Pressure for Bursting Disc (Mpa) | ||||

| LNG | LO2 | LN2 | LAr | LCO2 | ||||||||

| DPL Series - Vertical Cylinders | 80 | 2.3 | 85 | 31 | 87 | 62 | 107 | 84 | φ516*907 | 2.41 | / | 3.6 |

| 100 | 2.3 | 95 | 38 | 120 | 77 | 133 | 105 | φ516*1037 | 2.41 | / | 3.6 | |

| 175 | 1.37 | 116 | 67 | 190 | 135 | 233 | 183 | φ516*1507 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 133 | 2.41 | / | 3.6 | ||||||||

| 2.88 | 146 | 3.45 | 5.17 | |||||||||

| 3.45 | 164 | 4.14 | 5.17 | |||||||||

| 195 | 1.37 | 125 | 75 | 212 | 150 | 260 | 204 | φ516*1632 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 145 | / | 2.41 | / | 3.6 | |||||||

| 2.88 | 158 | 3.45 | 5.17 | |||||||||

| 3.45 | 185 | 4.14 | 5.17 | |||||||||

| 210 | 1.37 | 135 | 81 | 228 | 162 | 280 | 220 | φ516*1717 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 150 | / | 2.41 | / | 3.6 | |||||||

| 2.88 | 166 | 3.45 | 5.17 | |||||||||

| 3.45 | 191 | 4.14 | 5.17 | |||||||||

| 232 | 1.37 | 148 | / | 252 | / | / | / | φ516*1910 | 1.59 | / | 2.4 | |

| 410 | 1.37 | 325 | 157 | / | / | / | / | 890*870*1770 | 1.59 | 2.41 | / | |

| 500 | 1.37 | 360 | 192 | 542 | 384 | 665 | 523 | 890*870*2000 | 1.59 | 2.41 | / | |

| 2.3 | 407 | / | 2.41 | / | 3.6 | |||||||

| 3.17 | 448 | 3.45 | 5.17 | |||||||||

| DPW Series - Horizontal Cylinders | 410 | 1.59 | 342 | 158 | / | / | / | / | 1850*820*1020 | 1.9 | 2.41 | 2.4 |

| 499 | 1.59 | 353 | 192 | 541 | 383 | 664 | 522 | 2100*820*1020 | 1.9 | 2.41 | 2.4 | |

| 2.1 | 406 | / | 2.86 | / | 3.6 | |||||||

| 2.5 | 420 | 2.86 | 3.6 | |||||||||

| 3.45 | 510 | 4.15 | 5.17 | |||||||||

Main Features:

1. High vacuum insulation technology is applied to achieve higher cost performance.

2. Ultrasonic flaw detection, high quality inspection.

3. Complete with level gauge and pressure gauge and other necessary fittings

4. Famous brand pressure relief valve

Dewar Cylinder Main Technical Parameters:

Full Volume: 80L/100L/175L/195L/210L/232L/410L/500L/1000L

Work Pressure: 1.37MPa/2.3MPa/2.88MPa/3.45MPa

Inner Tank Design Temperature: -196℃

External Tank Design Temperature: -20℃~+50℃

Insulation: Vacuum with Multi-layer Wrapped

Stored Medium: LO2,LN2,LAr,LCO2,LNG

Inner Tank Material: SS304 08 or SA240

Shell Tank Material: Q345R or SS304 08

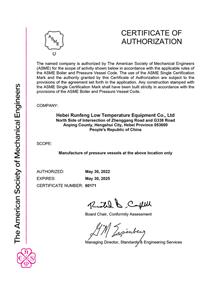

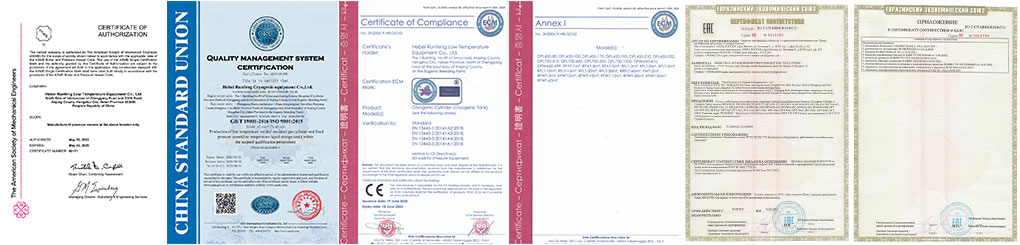

Qualification Certification:

ASME VIII DIV.1, CE PED/TPED, Russia EAC, China GB, ISO9001:2015

Detailed Images

S30408 Refined Polish Each of our cylinder must strictly go through degreasing and refined polish. | Digitail level gauge Optional we provide digital level gauge for option, which is show by precision percentage. | Anti-Shock Rubber Cushion The thicken rubber cushion can greatly prevent the inner container from any sudden shock and bufferthe impact. |

25 layers of Vacuum insulated quilt We use 25 layers of mutiple thermal insulated quilt to ensure the vacuum effectiveness. | Protective ring. Each of our cylinder has two protective rings to protect the brass vaporizer coils and pressure built coils from any deformation | Firm Foundation Structure. Our DPL-450L&410L serials are all fabricated by bolts and nuts with strong frame foundation. |

Certifications

-

Download

- Technical Chart_Cylinders.pdf