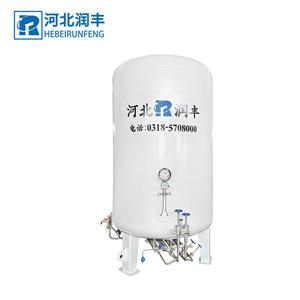

Liquid Co2 Tank

Brand :HEBEI RUNFENG

Product origin :China

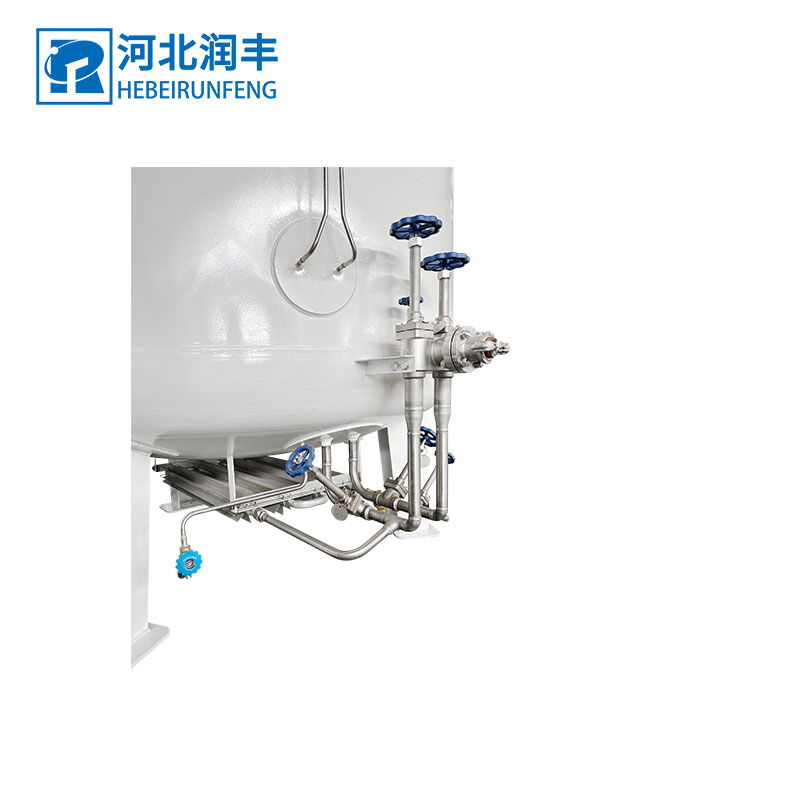

Liquid Co2 Tank, the company adopts automated equipment testing and production, which improves production efficiency. Significantly reduces the time to deliver products to customers. Short delivery time, good thermal insulation performance and competitive price are the biggest advantages of our products. It can be produced according to customer-specified valves, pipes, and specified locations. Can be customized according to customer needs.

Product Description

Liquid Co2 Tank, the company adopts automated equipment testing and production, which improves production efficiency. Significantly reduces the time to deliver products to customers. Short delivery time, good thermal insulation performance and competitive price are the biggest advantages of our products. It can be produced according to customer-specified valves, pipes, and specified locations. Can be customized according to customer needs.

Model: 1m³--500m³

Pressure: 2.2Mpa---3.0Mpa

Application scenarios: industrial welding, food production, plant breeding, engineering construction, etc.

Capacity: 1m³---200m³ 100 units per month

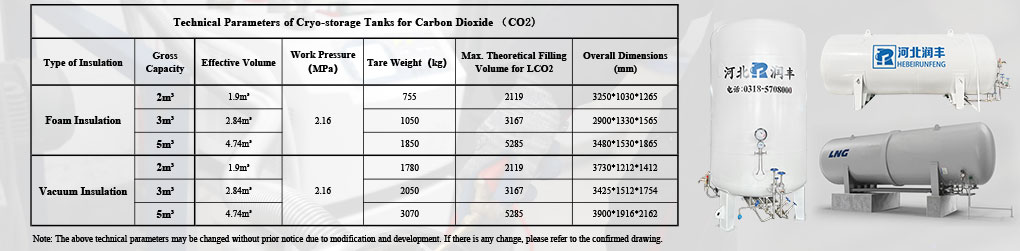

Specification

Main Features

1.Many years experience in cryogenic liquid storage tank's designing and manufacturing.

2.Professional and powerful team to support the business of our company.

3.Superior raw material to make the high quality products.

4.Various kinds of cryogenicliquid storage tank can be proveded for and customized products can also be accepted.

Detailed Images

Metal Sheet Rolling | S30408 Inner Tank Weldin | Head top welding |

Internal piping design | Pipe assembly | Finish product Inspection |

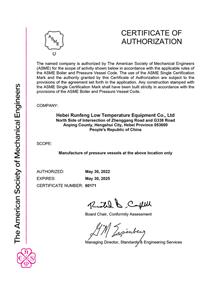

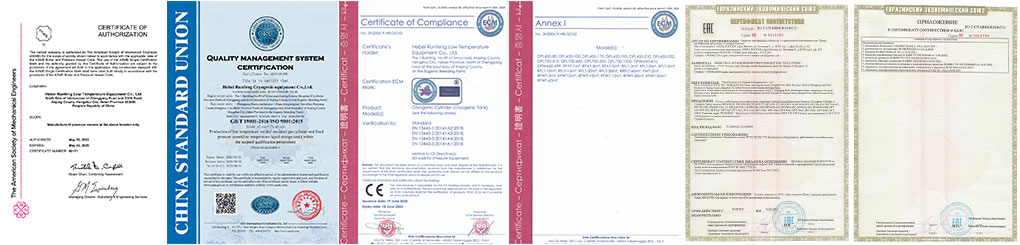

Certifications

-

Download

- tanks技术信息表.pdf