Liquid Nitrogen Cylinder

Brand :HEBEI RUNFENG

Product origin :China

Delivery time :0~35days

Supply capacity :3000 pcs per month

Liquid Nitrogen Dewar bottles are mainly used for filling, storing and transporting for liquid nitrogen. The inner and outer tanks of the product are made of 304 stainless steel. The LIN Dewars adopt high vacuum winding technology to ensure better thermal insulation effect and longer service life of the product. It can be used in medical treatment, biological research, university experiments, epidemic prevention units, etc. Its use conforms to the development of society and satisfies different customer groups. According to customer needs, we can provide various capacities or volumes from 80L to 1000L.

Product Description

Liquid Nitrogen Dewar is mainly used for filling, storing and transporting liquid nitrogen. The inner and outer tanks of the product are made of 304 stainless steel. The product adopts high vacuum winding technology to ensure better thermal insulation effect and longer service life of the product. It can be used in medical treatment, biological research, university experiments and epidemic prevention units. Its use conforms to the development of society and satisfies different customer groups. According to the needs of customers, we can provide different specifications of 80L-1000L products.

Specification

| Overall Dimensions and Technical Parameters for Liquid Cylinders | ||||||||||||

| Type | Gross Capacity (L) | Working Pressure (MPa) | Tare Weight(Kg) | Max. Theoretical Max. Filling Volume(Kg) | Overall Dimension(mm) | Safety Valve Setting Pressure | Secondary Safety Valve for LNG (Mpa) | Bursting Pressure for Bursting Disc (Mpa) | ||||

| LNG | LO2 | LN2 | LAr | LCO2 | ||||||||

| DPL Series - Vertical Cylinders | 80 | 2.3 | 85 | 31 | 87 | 62 | 107 | 84 | φ516*907 | 2.41 | / | 3.6 |

| 100 | 2.3 | 95 | 38 | 120 | 77 | 133 | 105 | φ516*1037 | 2.41 | / | 3.6 | |

| 175 | 1.37 | 116 | 67 | 190 | 135 | 233 | 183 | φ516*1507 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 133 | 2.41 | / | 3.6 | ||||||||

| 2.88 | 146 | 3.45 | 5.17 | |||||||||

| 3.45 | 164 | 4.14 | 5.17 | |||||||||

| 195 | 1.37 | 125 | 75 | 212 | 150 | 260 | 204 | φ516*1632 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 145 | / | 2.41 | / | 3.6 | |||||||

| 2.88 | 158 | 3.45 | 5.17 | |||||||||

| 3.45 | 185 | 4.14 | 5.17 | |||||||||

| 210 | 1.37 | 135 | 81 | 228 | 162 | 280 | 220 | φ516*1717 | 1.59 | 2.41 | 2.4 | |

| 2.3 | 150 | / | 2.41 | / | 3.6 | |||||||

| 2.88 | 166 | 3.45 | 5.17 | |||||||||

| 3.45 | 191 | 4.14 | 5.17 | |||||||||

| 232 | 1.37 | 148 | / | 252 | / | / | / | φ516*1910 | 1.59 | / | 2.4 | |

| 410 | 1.37 | 325 | 157 | / | / | / | / | 890*870*1770 | 1.59 | 2.41 | / | |

| 500 | 1.37 | 360 | 192 | 542 | 384 | 665 | 523 | 890*870*2000 | 1.59 | 2.41 | / | |

| 2.3 | 407 | / | 2.41 | / | 3.6 | |||||||

| 3.17 | 448 | 3.45 | 5.17 | |||||||||

| DPW Series - Horizontal Cylinders | 410 | 1.59 | 342 | 158 | / | / | / | / | 1850*820*1020 | 1.9 | 2.41 | 2.4 |

| 499 | 1.59 | 353 | 192 | 541 | 383 | 664 | 522 | 2100*820*1020 | 1.9 | 2.41 | 2.4 | |

| 2.1 | 406 | / | 2.86 | / | 3.6 | |||||||

| 2.5 | 420 | 2.86 | 3.6 | |||||||||

| 3.45 | 510 | 4.15 | 5.17 | |||||||||

Main Applications

1.to fill liquid oxygen for medical use, as an equipment for providing LO2;

2.to fill oxygen for the cutting, welding, and heating of metal in industry;

3.to fill liquid argon for argon-arc welding and other protection occasion of argon;

4.to fill liquid nitrogen for the protective use by high nitrogen, and the field of food, pharmaceutical, biotech, superconduction etc.

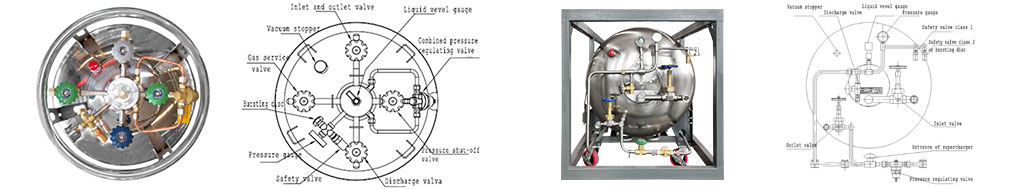

Detailed Images

S30408 Refined Polish Each of our cylinder must strictly go through degreasing and refined polish. | Digitail level gauge Optional we provide digital level gauge for option, which is show by precision percentage. | Anti-Shock Rubber Cushion The thicken rubber cushion can greatly prevent the inner container from any sudden shock and bufferthe impact. |

25 layers of Vacuum insulated quilt We use 25 layers of mutiple thermal insulated quilt to ensure the vacuum effectiveness. | Protective ring. Each of our cylinder has two protective rings to protect the brass vaporizer coils and pressure built coils from any deformation | Firm Foundation Structure. Our DPL-450L&410L serials are all fabricated by bolts and nuts with strong frame foundation. |

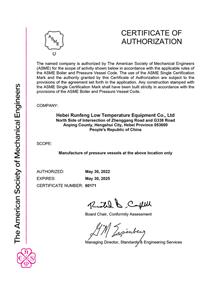

Certifications