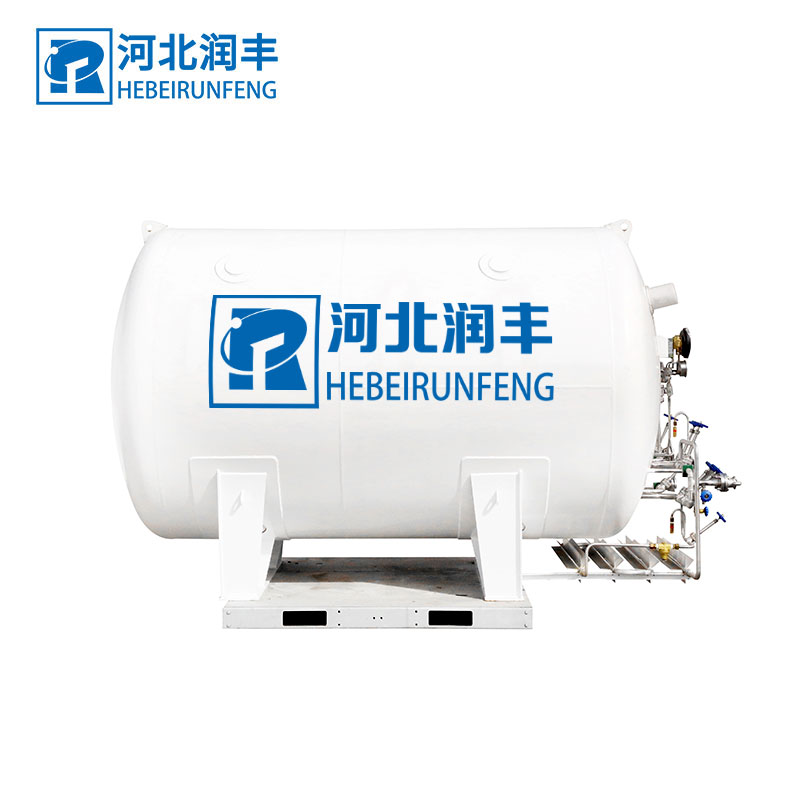

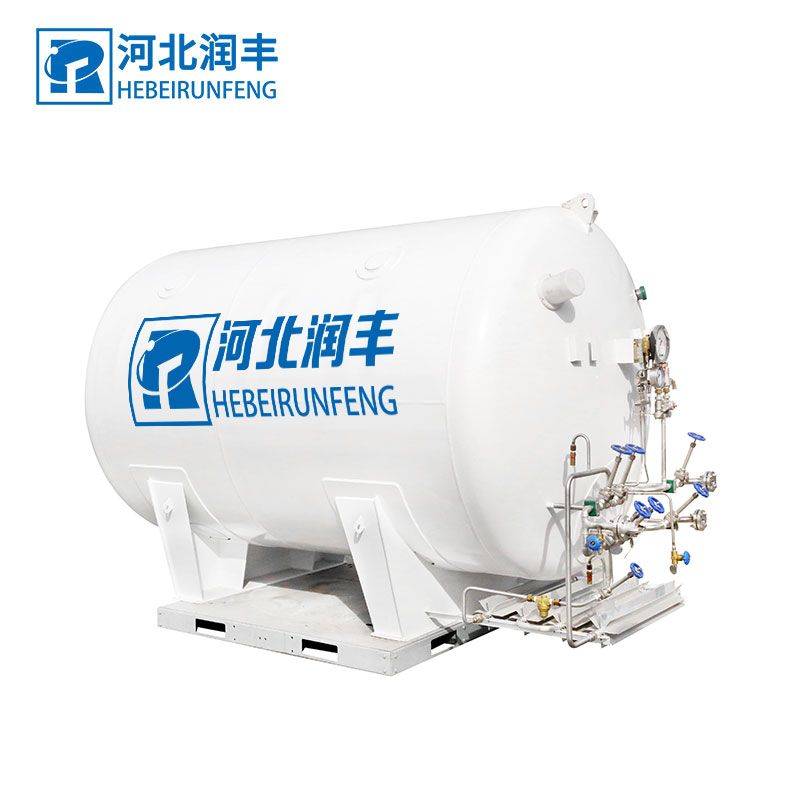

Liquid Nitrogen Storage Tank

Brand :HEBEI RUNFENG

Product origin :China

Delivery time :0~90days

Supply capacity :7000 pcs per year

Liquid Nitrogen Storage Tank, mainly used for filling and storing of liquid nitrogen (LN2). We can supply tanks in different volumes, from 1m³ to 300 m³. The cryogenic storage tank mainly adopts the high vacuum multi-layer winding technology, which makes our products more competitive in cost and weight and the the proformance of vacuum status and maintenance time is satisfactory. Our MLI insulation tanks are more conducive to the transportation and the use for customers. The products mainly consists of 304 stainless steel inner liner and carbon steel outer liner. The tank material and flow can be customized according to customer needs. The working pressure is mainly 0.8Mpa, 1.6Mpa, 2.0Mpa, 3.5Mpa.

Product Description

Liquid Nitrogen Storage Tank, mainly used for filling and storing of liquid nitrogen (LN2). We can supply tanks in different volumes, from 1m³ to 300m³. The cryogenic storage tank mainly adopts the high vacuum multi-layer winding technology, which makes our products more competitive in cost and weight. Compared to storage tanks with perlite vacuum, MLI insulation tanks are lighter in weight. It is more conducive to the transportation of products and the use for customers. The products mainly consist of 304 stainless steel inner liner and carbon steel outer liner. Can be customized according to customer needs. The working pressure is mainly 0.8Mpa, 1.6Mpa, 2.0Mpa, 3.5Mpa.

Specification

| Vertical Storage Tank Technical Information Sheet | ||||||||||

| Geometric Volume | Work Pressure (MPa) | Liquid Gases Weight(kg) | Tare Weight (kg) | Inner vessel | Outer vessel | Overall Dimensions (mm) | ||||

| LO2 | LN2 | LAR | LNG | LCO2 | ||||||

| 1 | ≤0.80 | 1083 | 769 | 1339 | 404 | / | 825 | SS30408 | SS30408/Q345R | 2400*1413*1301 |

| ≤1.60 | / | 825 | ||||||||

| ≤2.30 | 1059 | 825 | ||||||||

| ≤3.45 | / | 940 | ||||||||

| 2 | ≤0.80 | 2166 | 1539 | 1679 | 796 | / | 1135 | SS30408 | SS30408/Q345R | 2851*1786*1750 |

| ≤1.60 | / | 1135 | ||||||||

| ≤2.30 | 1915 | 1248 | ||||||||

| ≤3.45 | / | 1433 | ||||||||

| 3 | ≤0.80 | 3237 | 2300 | 4004 | 1047 | / | 1590 | SS30408 | SS30408/Q345R | 3592*1785*1750 |

| ≤1.60 | / | 1590 | ||||||||

| ≤2.30 | 3166 | 1850 | ||||||||

| ≤3.45 | / | 2025 | ||||||||

| 5 | ≤0.80 | 5118 | 3636 | 6330 | 1917 | / | 2334 | SS30408 | SS30408/Q345R | 3690*1870*2152 |

| ≤1.60 | / | 2334 | ||||||||

| ≤2.30 | 5085 | 2425 | ||||||||

| ≤3.45 | / | 2867 | ||||||||

| 8 | ≤0.80 | 8664 | 6156 | 10716 | 3035 | / | 3755 | SS30408 | SS30408/Q345R | 5130*1950*2196 |

| ≤1.60 | / | 3848 | ||||||||

| ≤2.30 | 7950 | 4187 | ||||||||

| ≤3.45 | / | 4867 | ||||||||

| 10 | ≤0.80 | 10818 | 7686 | 13380 | 4012 | SS30408 | SS30408/Q345R | 5800*1950*2196 | ||

| ≤1.60 | 4112 | |||||||||

| ≤2.30 | 4527 | |||||||||

| ≤3.45 | 5360 | |||||||||

| 15 | ≤0.80 | 16245 | 11542 | 19978 | 6060 | SS30408 | SS30408/Q345R | 8320*2196*2227 | ||

| ≤1.60 | 6451 | |||||||||

| ≤2.30 | 7055 | |||||||||

| ≤3.45 | 8267 | |||||||||

| 20 | ≤0.80 | 21181 | 15050 | 26197 | 7441 | SS30408 | SS30408/Q345R | 10320*2196*2227 | ||

| ≤1.60 | 7921 | |||||||||

| ≤2.30 | 8696 | |||||||||

| ≤3.45 | 10251 | |||||||||

| 25 | ≤0.80 | 27075 | 19237 | 33487 | 11940 | SS30408 | SS30408/Q345R | 11675*2501*2541 | ||

| ≤1.60 | 13340 | |||||||||

| ≤2.30 | 14275 | |||||||||

| ≤3.45 | 16150 | |||||||||

| 30 | ≤0.80 | 32490 | 23085 | 40185 | 10395 | SS30408 | SS30408/Q345R | 11400*2675*2753 | ||

| ≤1.60 | 11920 | |||||||||

| ≤2.30 | 12940 | |||||||||

| 40 | ≤0.80 | 43320 | 30780 | 53580 | 13578 | SS30408 | SS30408/Q345R | 14560*2675*2749 | ||

| ≤1.59 | 15637 | |||||||||

| 50 | ≤0.80 | 54150 | 38475 | 66975 | 14221 | SS30408 | SS30408/Q345R | 11413*3359*3450 | ||

| ≤1.60 | 16860 | |||||||||

| 60 | ≤0.80 | 64980 | 46170 | 80370 | 16322 | SS30408 | SS30408/Q345R | 13397*3355*3230 | ||

| ≤1.59 | 19237 | |||||||||

| 80 | ≤0.80 | 87107 | 61892 | 107738 | 26218 | SS30408 | SS30408/Q345R | 13750*3673*3750 | ||

| ≤1.59 | 29903 | |||||||||

| 100 | ≤0.80 | 108300 | 76950 | 133950 | 31043 | SS30408 | SS30408/Q345R | 16483*3673*3750 | ||

| ≤1.59 | 35577 | |||||||||

Main Features

1. Many years experience in cryogenic liquid storage tank's designing and manufacturing.

2. Professional and powerful technical teams ensures high quality standard.

3. Superior raw material to make the high quality products.

4. Various kinds of cryogenic liquid storage tank can be provided. Customized tanks can be produced here.

Detailed Images

Metal Sheet Rolling | S30408 Inner Tank Weldin | Head top welding |

Internal piping design | Pipe assembly | Finish product Inspection |

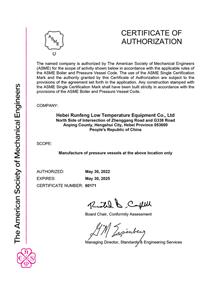

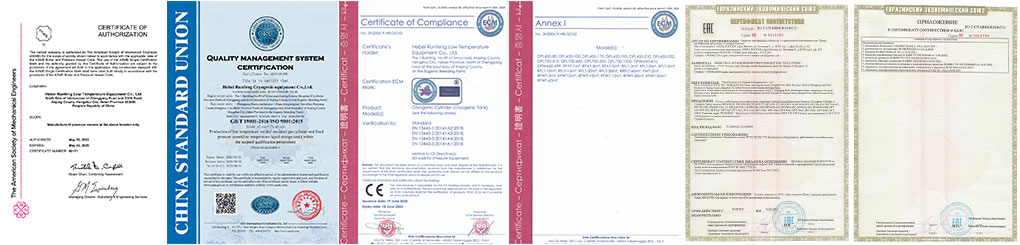

Certifications

-

Download

- tanks技术信息表.pdf