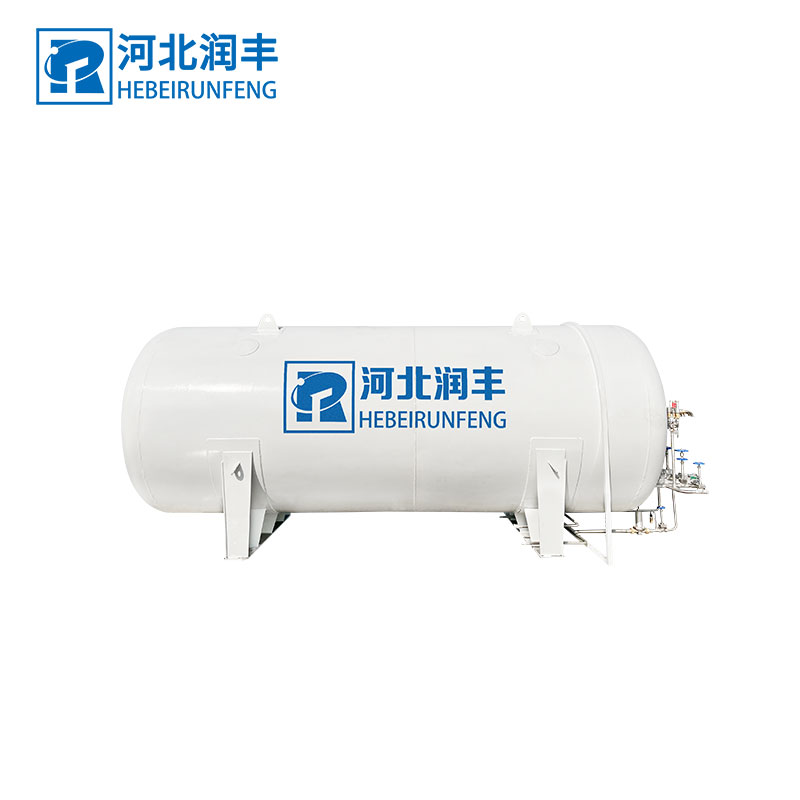

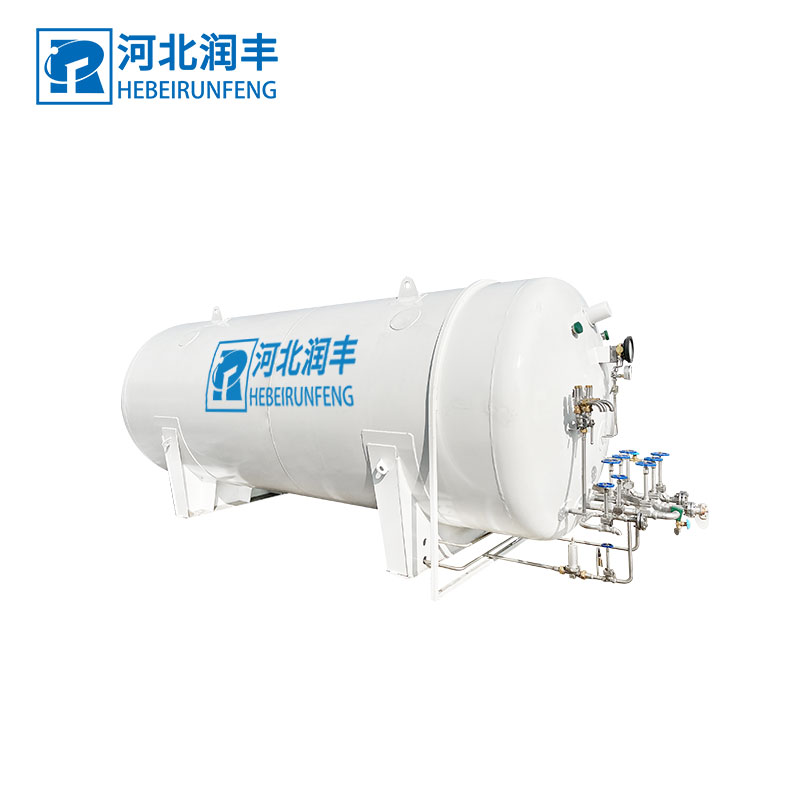

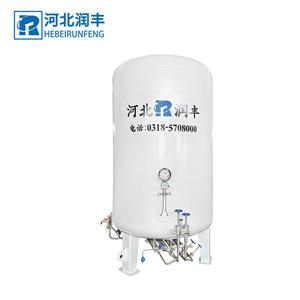

Liquid Oxygen Storage Tank

Brand :HEBEI RUNFENG

Product origin :China

Liquid Oxygen Storage Tank, mainly used for filling and storing liquid oxygen (LO2). The use of thermal insulation is wrapped in a vacuum layer, making the product lighter and easier to transport. Reasonable internal structure space and real-time online detection of vacuum technology ensure the quality of our products. Generally, the inner tank material of the product is 304 stainless steel, and the outer tank material is carbon steel. Customized production can be carried out according to the requirements of the customer's use environment. The working pressure range of the storage tank is 0.8Mpa--3.5Mpa. Customers can choose

Product Description

Liquid Oxygen Storage Tank, mainly used for filling and storing liquid oxygen (LO2). The use of thermal insulation is wrapped in a vacuum layer, making the product lighter and easier to transport. Reasonable internal structure space and real-time online detection of vacuum technology ensure the quality of our products. Generally, the inner tank material of the product is 304 stainless steel, and the outer tank material is carbon steel. Customized production can be carried out according to the requirements of the customer's use environment. The working pressure range of the storage tank is 0.8Mpa--3.5Mpa. Customers can choose

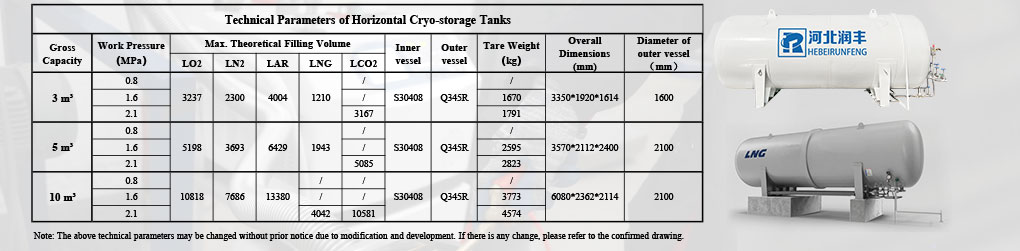

Specification

Main Features

1.Many years experience in cryogenic liquid storage tank's designing and manufacturing.

2.Professional and powerful team to support the business of our company.

3.Superior raw material to make the high quality products.

4.Various kinds of cryogenicliquid storage tank can be proveded for and customized products can also be accepted.

Detailed Images

Metal Sheet Rolling | S30408 Inner Tank Weldin | Head top welding |

Internal piping design | Pipe assembly | Finish product Inspection |

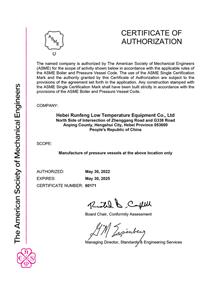

Certifications

-

Download

- tanks技术信息表.pdf